ENVENTIVE® CONCEPT

Tolerance Analysis Software

for Fit and Function

Looking to improve mechanical design analysis of variability or overcome the limitations of 1D stackup analysis with spreadsheets?

With Enventive concept, mechanical designers gain immediate insights on the impacts of geometric dimensioning and tolerancing (GD&T) decisions on a product’s fit for assembly and functionality. Concept helps meet all requirements with the first prototype.

Unlike spreadsheets or any other available tolerance analysis software, you optimize tolerances for both assembly fit and functional requirements, such as for forces, moments, deflections, wear, motion paths, gaps, thermals, and more.

The results: you optimally balance manufacturing costs with quality, avoid disruptive redesigns, cut scrap, and reduce warranty claims.

Using spreadsheets for anything beyond simple 1D stackup analysis requires an impractical level of mathematics involving angles, cosines, sines, and other complex calculations.

This is why mechanical designers and engineers dislike doing stackups.

Instead, they want to focus on the mechanics rather than the mathematics. This is what Enventive Concept is all about.

Whether you’re directly modeling mechanical systems by importing them from CAD or as functional 2D sketches, Concept guides your tolerance analysis by automatically detecting and ranking all stack contributors. Our intuitive geometric and dimensional modeling interface frees engineering teams to focus on critical aspects of a product’s mechanical design. No need for an expert to determine the best balance between cost and quality for a targeted PPM failure rate; Concept takes care of the math for you.

Ready to IMPROVE YOUR TOLERANCE ANALYSIS?

Book your free demo to see how Enventive Concept uniquely models and what-if simulates failure rates of requirements, such as for forces, moments, deflections, motions, and gaps, as a function of tolerancing.

“Enventive Concept should be part of any Designer’s or Mechanical Design Engineer’s Toolbox.”

Engineering Leader

with Manufacturer on Fortune Global 500 List

BENEFITS OF TOLERANCE ANALYSIS SOFTWARE FOR ROBUST DESIGN

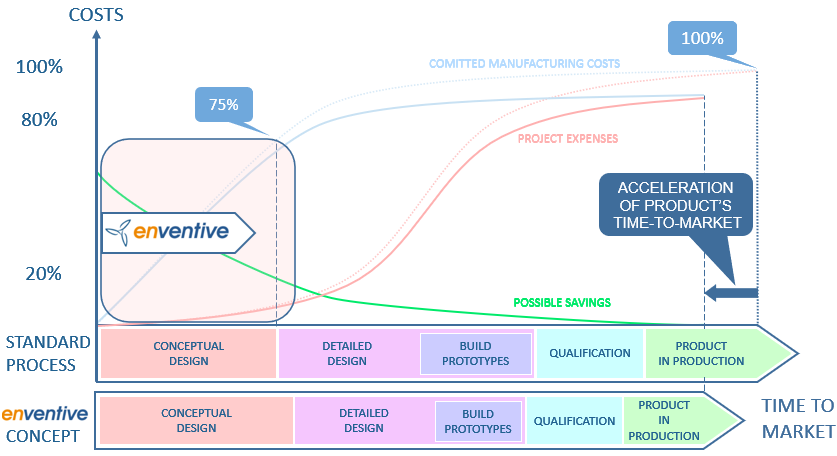

Enventive Concept cuts the duration of product design cycles by enabling engineering teams to make the right choices on critical nominal values and tolerances early in their design processes.

Enventive Concept follows Design For Six Sigma principles (DFSS). It is often used to solve critical manufacturing issues that were a result of past mistakes. Concept’s value starts during the design phase, before decisions related to the nominal 3D model are made. Thanks to sensitivity information, engineering teams can perform quick design iterations to balance optimization of tolerances and system geometry (nominal values). Engineering teams can create simple yet powerful models to reliably predict product design efficiency, a must at the RFQ level. With 70% of overall project costs resulting from these early design phase decisions, Enventive Concept quickly becomes strategic in reducing costs.

Enventive Concept takes into account all the complex aspects of your design, combined with tolerance and process capabilities from the earliest phases of the design cycle. Enventive Concept’s real-time calculation updates combined with intuitive dimensional and geometric modeling help you reliably determine the best balance between cost and quality for a targeted PPM (defect rate).

“Using Enventive Concept, we went from more than 1000 rejected units per week to zero, saving millions of dollars per year and ensuring a happy OEM customer.”

Director of Engineering

Electrical Device Supplier

Boost your confidence by using Enventive Concept for Simulation Driven Design to demonstrate product robustness to internal and external customers more professionally and at an early stage of the product development process.

With Concept, it’s possible to eliminate late tooling changes that can occur due to poor design choices on nominal values and tolerances.

ENVENTIVE CONCEPT KEY FEATURES

OUR CUSTOMERS

Our customers include those in Aeronautics, Appliances, Automotive, Industrial Equipment, Energy, Medical, Defense, Water Treatment, Automation, and Swiss Watches.

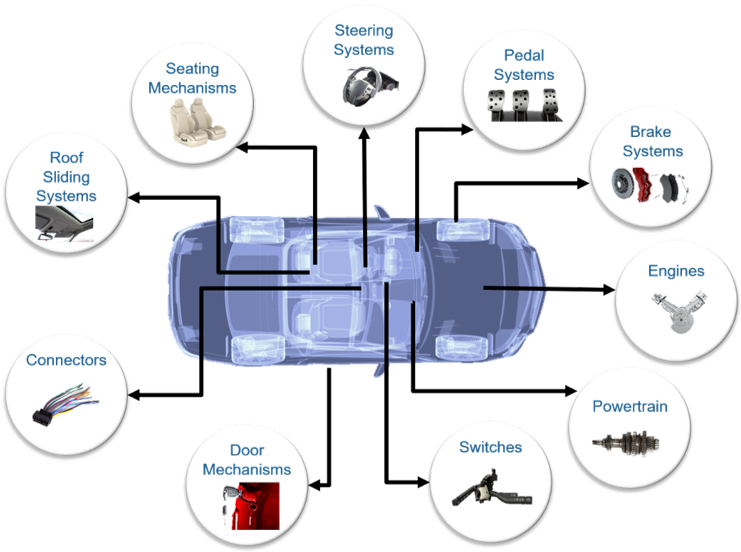

In the automotive industry, Enventive Concept is strategically used by:

At Request for Quotation (RFQ) stages for OEM suppliers, Enventive Concept is frequently used to create analyses that validate a design will robustly meet a customer’s requirements.

Learn more about Enventive Concept’s value in the Automotive Industry.

LEARN MORE

Further reading on our tolerance analysis software

Read up on Enventive Concept news

Check out our case studies, including Danfoss for fluid transfer, Brano for automotive, U-Shin for automotive, Wilo for pumps, Schneider Electric for circuit breakers, Idneo for electronic control units, and Bosch for power tools.

Learn about our other products: Enventive 3D&T and Enventive 360

ENVENTIVE CONCEPT

- CASE STUDIES

- BY INDUSTRY

- HIGHLIGHTED FEATURES

- SERVICES